NiAl cladding ufa wokhala ndi mphamvu yolumikizana mwamphamvu

Kufotokozera

Ndife onyadira kuyambitsa zinthu ziwiri zochokera ku ufa wa NiAl: KF-2 ndi KF-6.Zogulitsa ziwirizi zimagwiritsa ntchito magawo osiyanasiyana a ufa wa NiAl ndipo zimakhala ndi mawonekedwe apadera komanso ntchito.

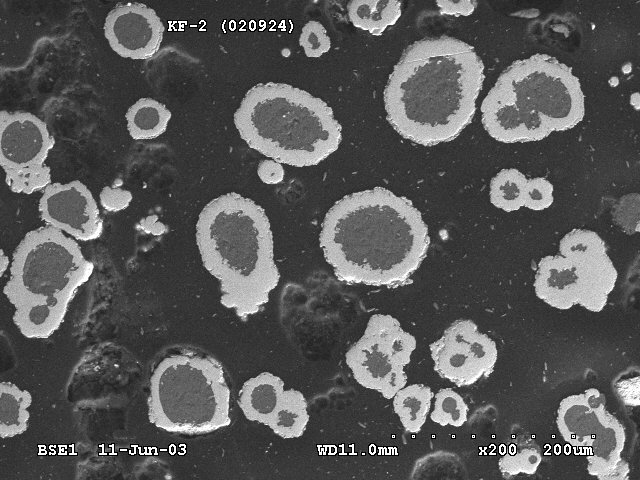

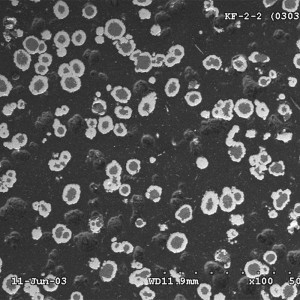

KF-2 imagwiritsa ntchito NiAl82/18, yomwe ili ndi 82% Ni ndi 18% Al.Izi ndizoyenera kugwiritsidwa ntchito ndi kutentha kwambiri kwa 650 ° C.Amapereka zokutira zowuma, zosunthika, zosagwirizana ndi oxidation, komanso zosavala zokhala ndi zodzigwirizanitsa zokha.Nthawi zonse pamakhala chiwopsezo chambiri pakupopera mbewu mankhwalawa, zomwe zimapangitsa kuti pakhale nyonga yabwino kwambiri yolumikizirana kuposa zinthu za Ni5Al.KF-2 ndi yoyenera kukonzanso ndi kupanganso machinable carbon steel ndi zitsulo zosagwira dzimbiri, ndipo itha kugwiritsidwanso ntchito pomanga zigawo za ceramic ndi zida zovala.

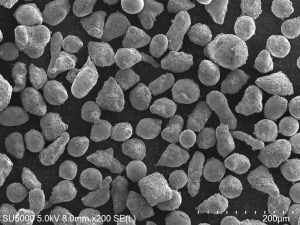

KF-6 imagwiritsa ntchito NiAl95/5, yomwe ili ndi 95% Ni ndi 5% Al.Izi ndizoyenera kugwiritsidwa ntchito ndi kutentha kwambiri kwa 800 ° C ndipo zitha kugwiritsidwa ntchito popopera mankhwala osiyanasiyana monga lawi, APS, ndi HVOF.Amaperekanso zokutira zowuma, zosunthika, zosagwirizana ndi oxidation, komanso zosavala zokhala ndi zodzigwirizanitsa zokha.Nthawi zonse pali exothermic anachita panthawi kupopera mbewu mankhwalawa, kuchititsa kwambiri kugwirizana mphamvu.KF-6 itha kugwiritsidwanso ntchito kukonzanso ndi kupanganso chitsulo chopangidwa ndi machinable carbon ndi zitsulo zosagwira dzimbiri, komanso zigawo zomangira za ceramic ndi zida zovala.

Mwachidule, onse a KF-2 ndi KF-6 ndi zinthu zopangidwa ndi NiAl ufa zomwe zimapereka mphamvu zomangirira komanso kukana kuvala.KF-2, yomwe ili ndi chiwerengero chochepa cha ufa wa NiAl (NiAl82 / 18), ndi yoyenera kwa ntchito ndi kutentha kwapakati pa 650 ° C, pamene KF-6, ndi kuchuluka kwa ufa wa NiAl (NiAl95/5), imatha kupirira kutentha kwambiri mpaka 800°C ndipo ingagwiritsidwe ntchito pogwiritsa ntchito njira zosiyanasiyana zopopera mankhwala.Zogulitsa zonsezi ndi zabwino kukonzanso ndi kupanganso makina opangidwa ndi zitsulo za carbon ndi zitsulo zosagwira dzimbiri, komanso zomangira zigawo za ceramic ndi zipangizo zovala.Kusankha pakati pa KF-2 ndi KF-6 kumatengera zofunikira za pulogalamuyo komanso kutentha kwakukulu komwe kumafunikira.

Zogulitsa zofanana

| Mtundu | Dzina lazogulitsa | AMPERIT | METCO/AMDRY | WOKA | Mtengo wa PRAXAIR | PAC |

| KF-2 | NdiAl82/18 | Chithunzi cha 404NS | ||||

| KF-6 | NdiAl95/5 | 282 | Mtengo wa 956450NS | NDI-109 | 906 |

Kufotokozera

| Mtundu | Dzina lazogulitsa | Chemistry (wt%) | Kuuma | Kutentha | Katundu & Kugwiritsa Ntchito | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MOS2 | WC | C | Fe | Ni | |||||

| KF-2 | NdiAl82/18 | 20 | Bali. | Mtengo wa HRC20 | ≤800ºC | •Flame, APS, Max.kutentha kwa ntchito 650 ° C. • Kusamva makutidwe ndi okosijeni wokhuthala komanso kuvala zosamva. | ||||||||

| KF-6 | NdiAl95/5 | 5 | Bali. | Mtengo wa HRC20 | ≤800ºC | •Flame, APS, HVOF, Max.kutentha kwa ntchito 800 ° C • Kusamva makutidwe ndi okosijeni wokhuthala komanso kuvala zosamva | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bali. | Mtengo wa HRC20 | ≤500ºC | • Amagwiritsidwa ntchito posindikiza zingwe zosunthika komanso mphete zomata zomata • Itha kugwiritsidwa ntchito ngati zinthu zochepa zokangana | ||||||||

| KF-21T | Ni-Graphite 75/25 | 25 | Bali. | Mtengo wa HRC20 | ≤480ºC | •Lawi, Max.kutentha kwa ntchito 480 ° C 1. Kuvala zipangizo za turbo compressor • Imagwira ntchito pazitsulo za nickel ndi zitsulo •Zogulitsa zomwe zili ndi ma graphite apamwamba ndizoyenera magawo a titaniyamu opanda m'mphepete • Zambiri za graphite zidzakulitsa ntchito yamafuta •Nickel yokhala ndi mafuta ambiri imathandizira kukana kukokoloka • Zogulitsa zofanana ndizosiyana chifukwa cha zosiyana za OEM | ||||||||

| KF-22T/R | Ni-graphite 60/40 | 50 | Bali. | Mtengo wa HRC20 | ≤480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bali. | Mtengo wa HRC20 | ≤480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | Bali. | Mtengo wa HRC40 | ≤800ºC | •Flame, APS, yosakhazikika • Itha kugwiritsidwa ntchito kusungunula crucible, terminal yosindikiza pamwamba ndi nkhungu pamwamba ngati wosanjikiza zoteteza | ||||||||

| KF-56 | Ni-WC 16/84 | Bali. | 12 | Mtengo wa HRC62 | ≤400ºC | •Flame, APS, yosakhazikika •Kukana kumenyedwa ndi nyundo, kukokoloka, kukwapulidwa ndi kutsetsereka | ||||||||

| KF-50 | Ni-WC10/90 | Bali. | 10 | Mtengo wa HRC62 | ≤400ºC | •Lawi lamoto, losakhazikika •Kukana kumenyedwa ndi nyundo, kukokoloka, kukwapulidwa ndi kutsetsereka | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | Bali. | 5.5 | Mtengo wa HRC40 | ≤550ºC | •Flame, APS, osasamba, Max.kutentha kwa ntchito 815 ° C. •Valani zinthu zokutira zosagwira, zomwe zitha kugwiritsidwa ntchito pokonza ma brake pad | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bali. | Mtengo wa HRC20 | ≤800ºC | •Flame, APS, Max.kutentha kwa ntchito 980 ° C. •Kupopera mbewu mankhwalawa ndi madzi a m'magazi ndi kudzigwirizanitsa | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | Mtengo wa HRC20 | ≤900ºC | •APS,HVOF, zosakhazikika, Max.kutentha kwa ntchito 980 ° C. • Imagwiranso ntchito pakukonza zomangira zomangira kutentha kwambiri kapena kuvala / kusinthidwa molakwika | |||||||||

| KF-133 | NdiMoAl | 5 | 5 | Bali. | Mtengo wa HRC20 | ≤ 650ºC | •Kudziphatikiza, zokutira zolimba zomwe zimagwiritsidwa ntchito ponyamula •Yolimba, yokhala ndi dzimbiri yabwino komanso magwiridwe antchito • Amagwiritsidwa ntchito pazigawo zamakina, mipando yonyamula ndi valavu | |||||||

| KF-31 | Ni-Diatomite 75/25 | •Flame, APS, yosakhazikika, Max.kutentha kwa ntchito 650 ° C. •Pakuti zokutira zosindikizira, kuphatikiza zisindikizo zosunthika, mphete zosindikizira, zomata zotsika. | ||||||||||||